Description

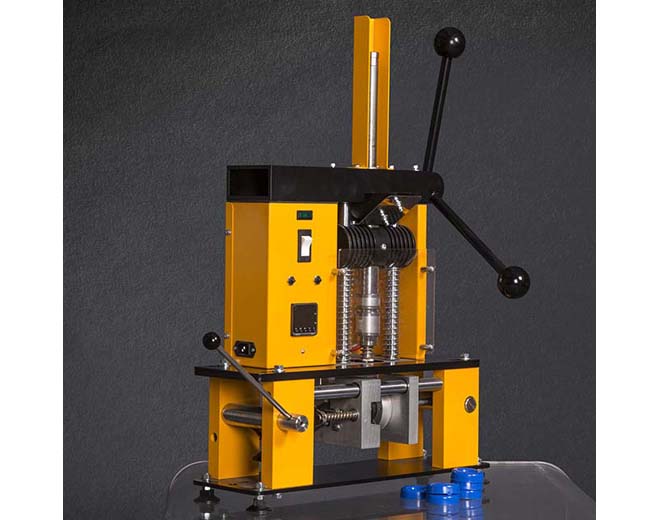

The 25 Injection Moulder provides a clear demonstration of injection moulding principles, whilst producing dense, production quality mouldings. Material to be injected is loaded into the machine through the hopper at the top of the temperature controlled heating barrel.

The mould is fitted into a vice assembly in the lower section of the machine, and is opened and closed using a over-centre locking mechanism. The vice also incorporates a stripper plate, so that if the mould incorporates suitable ejector pins then the product will be released after moulding. Adjustments in the vice assembly allow for different sizes of mould.

Typical materials that can be used on the 25 Injection Moulding Machine include polyethylene, polystyrene and polypropylene. The heated barrel can be operated at temperatures up to 200 degrees C, allowing other materials to also be processed.

Specifications:

| Voltage | 230 or 115V 50-60Hz |

| Max Current | 2 Amps (230V), 4 Amps (115V) |

| Mould Diameter | 75mm |

| Maximum Mould Thickness | 95mm |

| Maximum Moulding Weight | 20 grammes |

| Typical Cycle Time | 45 seconds |

| Typical Number of Cycles per Hour | 40 |

| Dimensions | 483 x 300 x 694mm |

| Weight | 29kg |