Bosch Rexroth’s hydraulics bench is really great! Robust, easy to use, and it offers the possibility to expand and add components to keep up with new technologies. My students are always motivated while working with the bench and I now understand why it has such a strong reputation. It is impossible to regret this purchase!

Marc Boudreau, Professor, Kativik SB

If you’re looking for the cutting edge in hydraulics training with the added benefit of green energy initiatives then you will definitely want to consider the optional Rexroth Sytronix Variable Speed Pressure Compensated Pump.

With Rexroth Sytronix, the pump controller automatically adjusts the drive speed of the pump to maintain constant pressure in the hydraulic system. The pump is sized to satisfy the peak demand of the hydraulic system, but for much of the cycle time the system will not need all that power. Much of that unneeded energy is wasted as heat. The energy input to the system is dynamic and matches the energy needed by the system. You’re no longer wasting energy and adding heat with extra flow bypassing a relief valve and noise is reduced.

In this way, the energy consumption can be reduced by up to 80%. With such savings, retrofitting older energy intensive applications will quickly pay for itself. Rexroth Sytronics is an industry leader helping us train a new generation of technicians who will implement these green energy solutions.

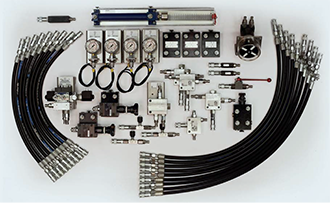

The valve set for mobile hydraulic principles is an introductory component set allows students to explore and discover hydraulic principles as they relate to mobile applications using typical mobile componentry.

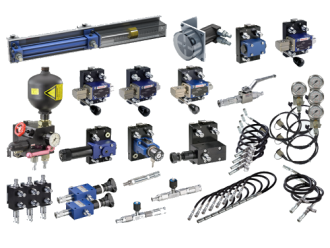

Bosch Rexroth’s DS2-NA and DS4-NA training system can cover multiple hydraulic and/or pneumatic training requirements on one common platform. Hardware and curriculum (student and teacher) support training on the following topics:

Hydraulics

Pneumatics

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

I have taught grade 9 applied science, science and technology, grade 10 applied, regular and enriched science, grade 11 chemistry and physics for 33 years at Westwood Senior High School in Hudson Québec. I discovered the PASCO equipment in 2019 and it completely changed my life. I love to discover, produce experiments and share discoveries. I am looking forward to work with your team.

Having graduated with a major in Computer Science and minors in Physics and Mathematics, I began my teaching career at Killarney Collegiate Institute in Killarney, Manitoba in 2009. While teaching Physics there, I decided to invest in PASCO products and approached the Killarney Foundation with a proposal about funding the Physics lab with the SPARK Science Learning System and sensors. While there I also started a tremendously successful new course that gave students the ability to explore their interests in science and consisted of students completing one project a month, two of which were to be hands-on experiments, two of which were to be research based, and the final being up to the student.

In 2011 I moved back to Brandon, Manitoba and started working at the school I had graduated from, Crocus Plains Regional Secondary School. In 2018 I finally had the opportunity to once again teach Physics and have been working hard to build the program. Being in the vocational school for the region has led to many opportunities to collaborate with our Electronics, Design Drafting, Welding, and Photography departments on highly engaging inter-disciplinary projects. I believe very strongly in showing students what Physics can look like and build lots of demonstrations and experiments for my classes to use, including a Reuben’s tube, an electromagnetic ring launcher, and Schlieren optics setup, just to name a few that have become fan favourites among the students in our building. At the end of my first year teaching Physics at Crocus Plains I applied for CERN’s International High School Teacher Programme and became the first Canadian selected through direct entry in the 21 years of the program. This incredible opportunity gave me the opportunity to learn from scientists working on the Large Hadron Collider and from CERN’s educational outreach team at the S’Cool Lab. Following this, I returned to Canada and began working with the Perimeter Institute, becoming part of their Teacher Network.

These experiences and being part of professional development workshops with the AAPT and the Canadian Light Source (CLS) this summer has given me the opportunity to speak to many Physics educators around the world to gain new insights into how my classroom evolves. As I work to build our program, I am exploring new ideas that see students take an active role in their learning, more inter-disciplinary work with departments in our school, the development of a STEM For Girls program in our building, and organizing participation in challenges from the ESA, the Students on the Beamline program from CLS, and our local science fair.

Though I graduated with a BEd qualified to teach English and Social Studies, it just wasn’t meant to be. My first job was teaching technology courses at a local high school, a far cry from the English and Social Studies job I had envisioned myself in. I was lucky enough to stay in that position for over ten years, teaching various technology courses in grades 10-12, while also obtaining a Master of Education in Technology Integration and a Master of Education in Online Instructional Media.

You will notice what is absent from my bio is any background in science. In fact, I took the minimum amount of required science courses to graduate high school. Three years ago I switched roles and currently work as a Technology Integration Leader; supporting teachers with integrating technology into their pedagogy in connection with the provincial outcomes. All of our schools have PASCO sensors at some level (mostly grades 4-12) and I made it my professional goal to not only learn how to use them, but to find ways to make them more approachable for teachers with no formal science background (like me!). Having no background or training in science has allowed me to experience a renewed love of Science, making it easier for me to support teachers in learning how to use PASCO sensors in their classrooms. I wholeheartedly believe that if more teachers could see just how easy they are to use, the more they will use them in the classroom and I’ve made it my goal to do exactly that.

I enjoy coming up with out-of-the-box ways of using the sensors, including finding curriculum connections within subjects outside of the typical science realm. I have found that hands on activities with immediate feedback, which PASCO sensors provide, help students and teachers see the benefits of technology in the classroom and will help more students foster a love of science and STEAM learning.