Description

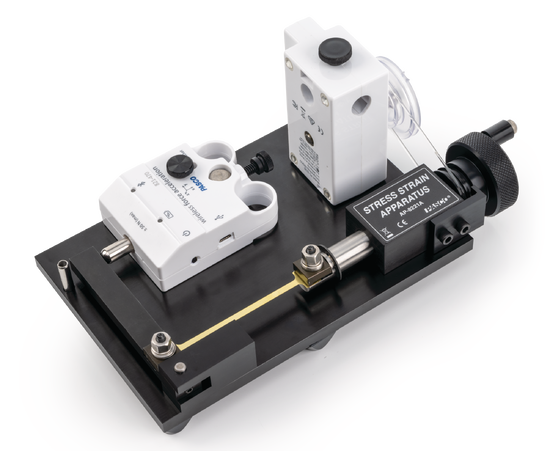

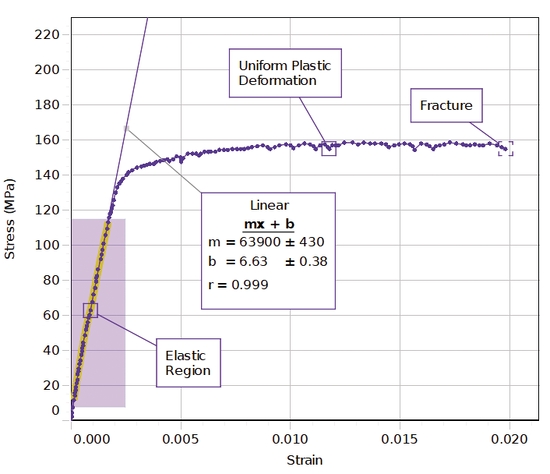

The objective of this lab is to find the relationship between tensile stress and strain for various materials. The Stress-Strain Apparatus stretches (and in some cases breaks) a test coupon while it measures the amount of stretch and force experienced by the test coupon. Software is used to generate a plot of stress versus strain, which allows Young’s Modulus, the elastic region, the plastic region, the yield point, and the break point to be ascertained.

Since the Stress-Strain Apparatus shows the entire stress versus strain curve, it is possible to measure a wide range of material properties including:

- Young’s Modulus

- Yield strength

- Tensile strength

- Ductility

- Toughness

Students can also compare the different curve shapes produced by various materials.

PASCO Capstone software allows students to determine Young’s Modulus by measuring the slope of the initial straight line (the elastic region) and to determine the toughness by integrating under the curve.

How It Works

Tension is applied to the sample by turning the knob by hand until the sample breaks. The force used to stretch the sample is measured using a Force Sensor connected via USB or Bluetooth. A metal lever provides a five-to-one mechanical advantage, increasing the maximum force that the sensor can read to 250 N.

The stress is calculated using Capstone by taking the force over the cross-sectional area. No adjustment is made for any change in the cross-sectional area during stretching.

The change in length of the sample is measured using a Rotary Motion Sensor. The resolution is 0.007 mm. The strain is calculated using Capstone by dividing the change in length by the original length.

What’s Included

- 1x Stress-Strain Apparatus without Sensors (AP-8221A)

- 1x Wireless Force Acceleration Sensor (PS-3202)

- 1x Wireless Rotary Motion Sensor (PS-3220)

- 1x Stress-Strain Apparatus Coupons, Plastic (AP-8222)

- 1x Stress-Strain Apparatus Coupons, Metal (AP-8223)

- 1x Digital Calipers (SE-8710)